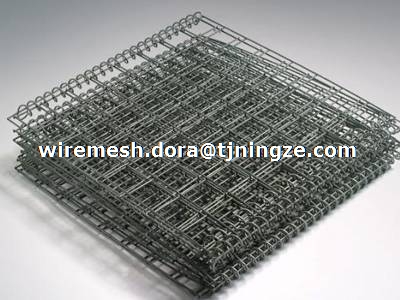

Welded gabion is made of high quality low carbon steel wire, in strict accordance with BS1052: 1986 standard through automation, precision and accurate processing machinery and equipment welding row after forming, then it use electro-galvanized, hot dip galvanized, coated, dip or Galfan and other processes where the surface passivation, plastics processing.

Welded gabions that assemble the front and rear panels, floor and partitions after forming, and then compressed, and the final package together with the network cover with spiral binding wire. All good lashing folded gabion products, is an independent entity. Spiral binding wire into the box away, in order to ensure quality, save in a dry environment.

Welded gabion box easy to install

Field installation is quick and easy. In fact, installation time can be as much as 40% less than required by hex type gabions. With diaphragms and stiffeners installed, the gabion may be filled with standard loading equipment. After filling the gabion, a lid is placed on top and secured with spiral binders, lacing wire or "C" rings.

Unlike hexagonal units, our welded wire Gabion hold their shape better – they don't bulge out when filled .They are easy to handle, which means more work, less labor and higher productivity in the job.

Our Welded wire Gabion are made by one of the nation's leading manufacturers of welded wire mesh. Each gabion is constructed of rugged hight tensile wire which is coated with a thick, corrosion-resistant layer of zinc. The wire is also available with a tough, durable PVC coating.